#DRIVEN OIL VISCOSITY CHART ISO#

However, in applications using oil rings and with oil levels reduced below the periphery of the lowermost bearing component, premium-grade synthetic ISO Grade 32 lubricants may have to be used simply because not all oil rings will work with thicker than ISO VG32 oils. In these instances, ISO Viscosity Grade 68 allows operation in a relatively wide range of ambient temperatures. In slow and medium speed pumps lubricant is usually applied with the oil level reaching to the center of bearing elements at the 6-o’clock position. But what if, at startup, the initial operating temperature is quite low and the oil will not flow? That’s what often happens when someone buys a standard “ multipurpose oil” without really thinking things through. Running a pump one might ultimately achieve an operating temperature that allows a certain thick oil to flow nicely. 3: Oil can become trapped behind the bearings if no oil return holes are provided (Ref. Also, thick oils can be quite difficult to apply with only the standard oil rings found in many pumps.įig. (As we then get short bearing life, the pump manufacturer will deny culpability and avoid class action suits). Sooner or later the stagnant puddle of oil will overheat and turn into tar, which is not good for bearings. 3), but thick oils get us into trouble with careless pump manufacturers who sometimes forget to put a drain hole at locations where bearings butt up against a shoulder (Fig. Thicker film oils are easily and reliably applied with oil mist methods (Ref. Thus intersecting at, say, VG 68, would tell us that this oil could be allowed to reach 92 degrees C and still satisfy our viscosity requirement of 11 cSt (Ref. 2 by entering the vertical y-scale at the required 11 cSt and, after intersecting a particular viscosity grade oil, plot down to read off the maximum allowable bearing operating temperature on the horizontal x-scale. VG 32 and, as long as our actual bearing operating temperature does not exceed our assumed temperature of 70 degrees C, we would now read off (from the vertical y-scale) an operating viscosity of 11 cSt-just right. (Important: We should always ascertain that our oil delivery system works with this thicker-than-needed oil.) We might pick ISO Entering the horizontal x-axis scale at 70 C and moving upwards to ISO VG 68 would allow us to read off 20 cSt on the vertical scale-close to twice what we need. 2, we must now either assume a certain bearing operating temperature, say, 70 degrees C or 158 degrees F. 2: For a required viscosity (vertical scale), the permissible bearing operating temperatures (horizontal scale) increases as thicker oils are chosen (diagonal lines)Ĭontinuing on Fig. As this thicker oil then reaches a higher operating temperature it will, hopefully, not “thin out” to a viscosity below 11 cSt.įig. Since oils become thinner when heated up and if our operating temperature is very high, we realize we should have selected a thicker oil. We have now established that, in this example, the minimum kinematic viscosity required to give adequate protection at operating temperature is 11 cSt. From there, move to the left and read off ~11 mm^2/s (a measure of viscosity that is more commonly called 11 centistokes, generally abbreviated as cSt. 1 at this calculated mean dimension and plot upward to intersect an imaginary 1,800 rpm diagonal line–just above the 2,000 rpm diagonal. Since dm = 0.5 (d+D), in this case dm = 92 mm. Suppose we were dealing with an 1,800 rpm pump and its bearings had bore diameters of 65 mm (dimension d) with bearing outer diameters (D) of 120 mm.

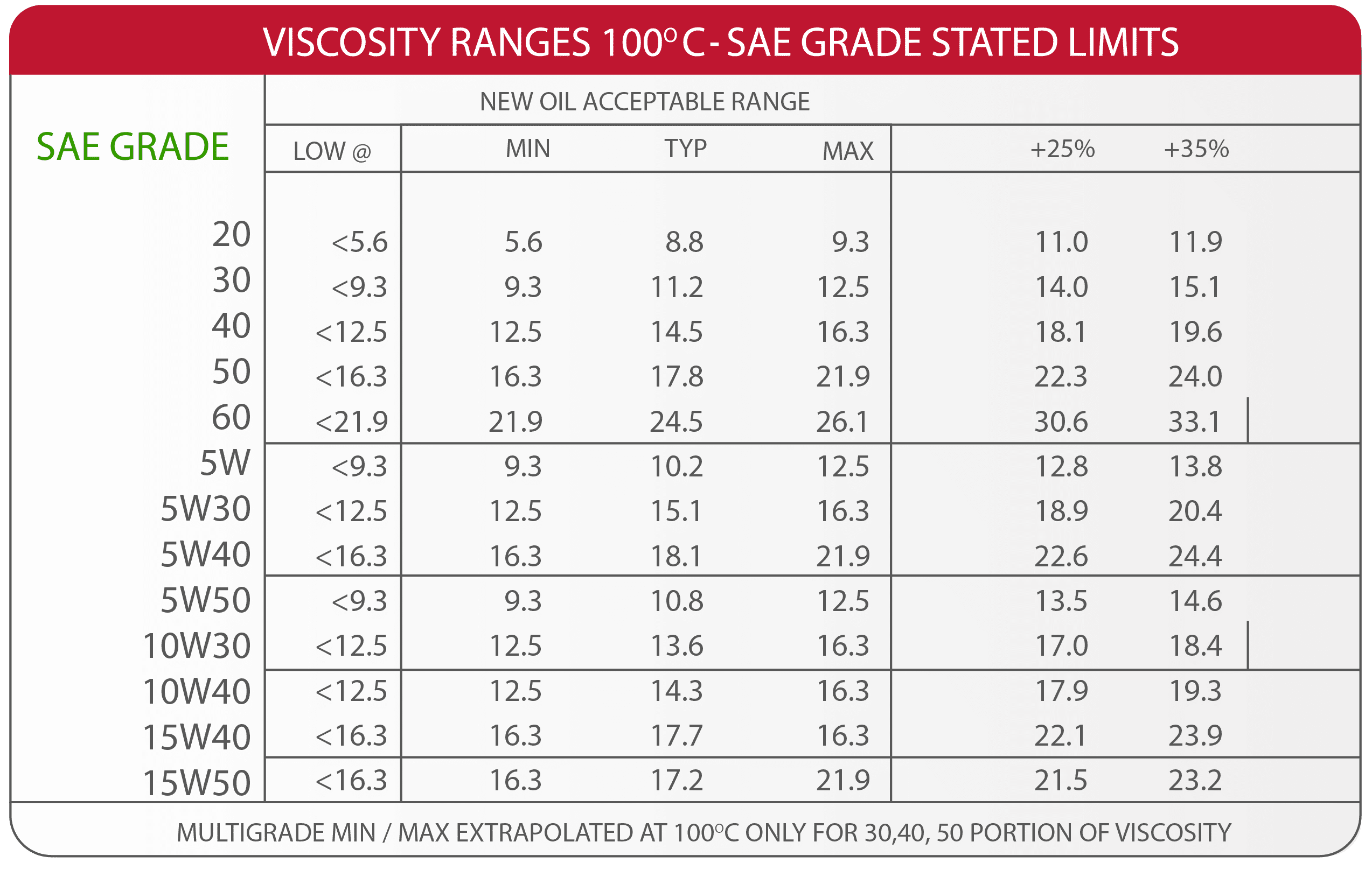

1 and 2 allow quick determination if a particular lubricant selection is in the right range.

#DRIVEN OIL VISCOSITY CHART HOW TO#

How to capture the benefits of thicker lubricants without actually using them or how to best apply ISO VG 68 and thicker oils will be one of our subjects.įigs. They are generally preferred over ISO Grade 32 lubricants.īut not all application methods are possible with ISO viscosity grades higher than VG 32.

For process pumps with rolling element bearings, ISO Grade 68 lube oils will allow higher operating loads. In general, thicker oil films will give better pump bearing protection than thinner oil films. Viscosity is by far the most important property of the lubricants applied to process pump bearings and recent, highly practical texts deal with the issue in great detail (Ref.

0 kommentar(er)

0 kommentar(er)